Bronze yog ib qho alloy raws li tooj liab. Cov khoom siv hlau tuaj yeem yog npib tsib xee, zinc, tin, aluminium thiab lwm yam. Hauv kab lus no, peb yuav txiav txim siab hom, thev naus laus zis, tshuaj lom neeg. muaj pes tsawg leeg ntawm bronze, raws li zoo raws li txoj kev rau nws manufacture.

Kev faib tawm

1. Raws li cov tshuaj muaj pes tsawg leeg, cov hlau no feem ntau muab faib ua ob pawg. Thawj yog tin bronzes. Nyob rau hauv lawv, tin yog lub ntsiab alloying khoom. Qhov thib ob yog tinless. Peb yuav tham txog qhov no ntxiv hauv qab no.

2. Raws li cov txheej txheem thev naus laus zis ntawm bronze, nws yog kev cai los faib rau hauv deformable thiab foundry. Cov qub tau ua tiav zoo nyob rau hauv siab. Cov yav tas yog siv rau cov zoo li tus castings.

Cov hlau no, piv rau tooj dag, muaj kev sib txhuam zoo dua, cov khoom siv kho tshuab, nrog rau kev tiv thaiv corrosion. Qhov tseeb, bronze yog ib qho alloy ntawm tooj liab thiab tin (raws li lub ntsiab auxiliary element). Nickel thiab zinc tsis yog cov ntsiab lus tseem ceeb ntawm no; rau qhov no, cov khoom siv xws li txhuas, tin, manganese, silicon, lead, hlau, beryllium, chromium, phosphorus, magnesium, zirconium thiab lwm yam.

Tin Bronzes: Foundry

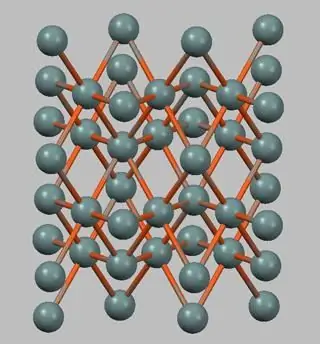

Cia peb saib seb lub hlau yog dab tsi. Tin bronze (daim duab hauv qab no qhia tau hais tias cov khoom cam khwb cia) yog ib qho hlau uas muaj fluidity qis dua lwm hom. Txawm li cas los xij, nws muaj qhov tsis tseem ceeb volumetric shrinkage, uas ua rau nws muaj peev xwm kom tau txais cov bronze castings. Cov khoom no txiav txim siab siv cov bronze nyob rau hauv lub casting ntawm antifriction qhov chaw. Tsis tas li ntawd, qhov kev txiav txim siab alloy yog siv rau hauv kev tsim cov khoom siv rau kev ua haujlwm hauv qhov nruab nrab aqueous (xws li dej hiav txwv) lossis hauv dej vapor, hauv cov roj thiab nyob rau hauv siab. Kuj tseem muaj lub npe hu ua non-standard casting bronzes rau lub luag haujlwm. Lawv yog siv nyob rau hauv zus tau tej cov bearings, zog, bushings, twj tso kua mis qhov chaw, sealing rings. Cov khoom no yog tsim los ua haujlwm nyob rau hauv kev kub siab, kev kub ceev thiab qis loads.

Ntaub bronzes

Qhov no subspecies ntawm foundry tin alloys yog siv nyob rau hauv kev tsim cov bearings, seals thiab zoo li tus castings. Cov bronzes no yog cov yam ntxwv ntawm cov khoom siv hluav taws xob tsawg, vim li ntawd, nyob rau hauv cov txheej txheem ntawm kev tsim cov bearings thiab bushings, lawv tsuas yog siv rau lub hauv paus steel nyob rau hauv daim ntawv ntawm ib txheej nyias nyias. Alloys nrog cov ntsiab lus siab ntawm tin muaj ntau dua txhua yam khoom. Yog li ntawd, lawv tuaj yeem siv yam tsis muaj steel thaub qab.

Tin Bronzes: Deformable

Alloys ua tiav los ntawm lub siab feem ntau muab faib ua pawg hauv qab no:tin-phosphorous, tin-zinc thiab tin-zinc-lead. Lawv tau pom lawv daim ntawv thov nyob rau hauv kev lag luam pulp thiab ntawv (nets yog tsim los ntawm lawv) thiab mechanical engineering (kev tsim cov springs, bearings thiab tshuab qhov chaw). Tsis tas li ntawd, cov ntaub ntawv no yog siv rau hauv kev tsim cov khoom siv bimetallic, rods, tapes, strips, gears, gears, bushings thiab gaskets rau cov cav tov heev, cov raj rau kev ntsuas, siab springs. Hauv kev tsim hluav taws xob, kev siv tooj liab dav dav (wrought) yog vim nws cov khoom siv hluav taws xob zoo heev (nrog rau cov yam ntxwv hluav taws xob siab). Nws yog siv rau hauv kev tsim cov khoom siv tam sim no-nqa, ntsaws txuas, tiv tauj. Nyob rau hauv kev lag luam tshuaj, tin bronzes yog siv los tsim lub caij nplooj ntoos hlav hlau, nyob rau hauv precision mechanics - fittings, nyob rau hauv daim ntawv kev lag luam - scrapers, nyob rau hauv lub tsheb thiab tsheb laij teb industries - bushings thiab bearings.

Cov alloys no tuaj yeem muab nkag rau hauv cov tawv tawv ntxiv, tawv, semi-hard thiab mos (annealed) xeev. Tin bronzes feem ntau yog ua haujlwm txias (dov los yog kos). Kub hlau tsuas yog nias. Nyob rau hauv siab, bronze ua hauj lwm zoo kawg nkaus ob qho tib si txias thiab kub.

Beryllium bronze

Qhov no yog ib qho alloy uas muaj nyob rau hauv pawg ntawm cov nag lossis daus hardening hlau. Nws muaj cov cuab yeej ua haujlwm siab, lub cev thiab elastic zog. Beryllium bronze muaj qib siab ntawm tshav kub tsis kam, corrosion kuj thiab cyclic zog. Nws yog resistant rau tsawgkub, tsis magnetize thiab tsis muab sparks thaum ntaus. Hardening ntawm beryllium bronzes yog nqa tawm ntawm qhov kub thiab txias ntawm 750-790 degrees Celsius. Qhov sib ntxiv ntawm cob alt, hlau thiab npib tsib xee pab txhawb kom qeeb tus nqi ntawm cov theem hloov pauv thaum kho cua sov, uas pab txhawb kev siv thev naus laus zis ntawm kev laus thiab hardening. Tsis tas li ntawd, qhov sib ntxiv ntawm npib tsib xee ua rau muaj qhov nce hauv qhov kub thiab txias, thiab manganese tuaj yeem hloov tau, txawm tias tsis yog tag nrho, kim beryllium. Cov yam ntxwv saum toj no ntawm bronze ua rau nws siv tau cov hlau no hauv kev tsim cov springs, caij nplooj ntoos hlav qhov chaw, thiab daim nyias nyias hauv kev lag luam saib.

Ib qho hlau ntawm tooj liab thiab manganese

bronze no muaj cov cuab yeej tshwj xeeb siab. Nws yog ua tiav los ntawm lub siab, ob qho tib si txias thiab kub. Cov hlau no yog tus cwj pwm los ntawm kev kub siab ua haujlwm, nrog rau kev tiv thaiv corrosion. Ib qho hlau ntawm tooj liab nrog qhov sib ntxiv ntawm manganese tau pom dav daim ntawv thov hauv qhov cub fittings.

Silicon bronze

Qhov no yog cov hlau nplaum uas muaj npib tsib xee, tsis tshua muaj manganese. Xws li ib tug hlau yog yus muaj los ntawm ultra-high mechanical, anti-kev sib txhuam thiab elastic zog. Nyob rau tib lub sijhawm, silicon bronze tsis poob nws cov plasticity ntawm qhov kub thiab txias. Cov hlau yog zoo soldered, ua tiav los ntawm kev siab ntawm ob qho tib si siab thiab qis kub. Cov hlau nyob rau hauv nqe lus nug yog tsis magnetized, tsis spark thaum ntaus. Qhov no piav qhia txog kev siv bronze (silicon) thoob plaws hauv kev tsim khoom hauv nkoj hauv nkoj hauv kev tsim khoom los tiv thaiv kev sib txhuam, bearings, springs,grates, evaporators, meshes thiab coj bushings.

Casting Tinless Alloys

hom tooj liab no yog tus yam ntxwv zoo corrosion, tiv thaiv kev sib txhuam, nrog rau lub zog siab. Lawv yog siv rau kev tsim khoom ntawm qhov chaw uas ua haujlwm hauv cov xwm txheej nyuaj tshwj xeeb. Cov no muaj xws li cov iav, li qub, bushings, lub zog rau lub zog turbines thiab cranes, worms uas ua hauj lwm nyob rau hauv tandem nrog hardened steel qhov chaw, bearings uas ua hauj lwm nyob rau hauv siab siab thiab shock loads.

Yuav ua li cas bronze?

Kev tsim cov hlau no yuav tsum tau nqa tawm hauv qhov cub tshwj xeeb uas siv rau smelting tooj liab alloys. Bronze tus nqi tuaj yeem ua los ntawm cov hlau tshiab los yog nrog ntxiv cov khoom pov tseg thib ob. Cov txheej txheem melting feem ntau yog ua nyob rau hauv ib txheej ntawm flux lossis charcoal.

Cov txheej txheem siv tus nqi ntawm cov hlau tshiab tshwm sim hauv ib ntus. Ua ntej, qhov xav tau ntawm flux lossis charcoal yog loaded rau hauv lub qhov cub kub heev. Ces tooj liab muab tso rau ntawd. Tom qab tos kom nws yaj, nce qhov kub thiab txias rau 1170 degrees. Tom qab ntawd, cov yaj yuav tsum tau deoxidized, uas yog ntxiv phosphorous tooj liab. Cov txheej txheem no tuaj yeem ua tiav hauv ob theem: ncaj qha rau hauv lub qhov cub, thiab tom qab ntawd hauv lub ladle. Nyob rau hauv cov ntaub ntawv no, lub additive yog qhia nyob rau hauv sib npaug proportions. Tom ntej no, qhov tsim nyog alloying ntsiab rhuab mus rau 120 degrees yog ntxiv rau yaj. Refractory Cheebtsam yuav tsum tau qhia nyob rau hauv daim ntawv ntawm ligatures. Ntxiv molten bronze (duab,Hauv qab no, ua kom pom cov txheej txheem smelting) yog nplawm kom txog thaum tag nrho cov khoom ntxiv tau yaj tag thiab ua kom sov rau qhov xav tau. Thaum muab cov txiaj ntsig tau los ntawm lub qhov cub, ua ntej nchuav, nws yuav tsum tau deoxidized thaum kawg nrog cov seem (50%) ntawm phosphorous tooj liab. Qhov no yog ua kom tso bronze los ntawm oxides thiab ua kom lub fluidity ntawm yaj.

Smelting los ntawm cov khoom siv rov ua dua

Yuav ua kom tooj liab siv cov hlau siv dua thiab pov tseg, melting yuav tsum ua raws li hauv qab no. Ua ntej, tooj liab yog yaj thiab deoxidized nrog phosphorus additives. Tom qab ntawd cov ntaub ntawv circulating yog ntxiv rau yaj. Tom qab ntawd, cov hlau yog tag nrho melted thiab alloying ntsiab lus qhia nyob rau hauv qhov tsim nyog ib theem zuj zus. Nyob rau hauv qhov kev tshwm sim uas tus nqi muaj ib tug me me ntawm cov ntshiab tooj liab, nws yog tsim nyog los ua ntej yaj cov circulating hlau, thiab ces ntxiv tooj liab thiab alloying ntsiab. Melting yog nqa tawm nyob rau hauv ib txheej ntawm flux los yog charcoal.

Tom qab melting qhov sib tov thiab cua sov rau qhov yuav tsum tau kub, qhov kawg deoxidation ntawm cov sib tov nrog phosphorous tooj liab yog nqa tawm. Tom ntej no, lub yaj yog them rau sab saum toj nrog calcined thee los yog qhuav flux. Kev noj qab haus huv yog 2-3 feem pua ntawm qhov hnyav ntawm cov hlau. Lub rhuab yaj yog khaws cia rau 20-30 feeb, tsis tu ncua stirred, thiab ces lub slag cais tawm ntawm nws nto. Txhua yam, bronze yog npaj txhij rau casting. Rau kev tshem tawm slag zoo dua, quartz xuab zeb tuaj yeem ntxiv rau lub ladle, uas ua rau nws thickens. Txhawm rau txiav txim siab seb lub bronze yog npaj txhij rau casting rau hauv pwm, tshwj xeebkev xeem. Qhov tawg ntawm cov qauv zoo li no yuav tsum tsis tu ncua thiab huv.

Aluminium Bronze

Nws yog ib qho hlau ntawm tooj liab thiab txhuas ua cov khoom siv alloying. Cov txheej txheem melting ntawm cov hlau no txawv heev los ntawm cov saum toj no, uas tau piav qhia los ntawm cov yam ntxwv ntawm cov khoom siv sib xyaw. Xav txog yuav ua li cas ua bronze siv aluminium alloying Cheebtsam. Hauv kev tsim cov hlau no siv cov khoom siv rov ua dua tshiab hauv cov nqi, kev ua haujlwm rau deoxidation nrog phosphorus Cheebtsam yog tsis siv. Qhov no yog vim lub fact tias phosphorus yog yus muaj los ntawm ib tug qis affinity rau oxygen molecules tshaj txhuas. Koj kuj yuav tsum paub tias hom tooj liab no yog qhov rhiab heev rau overheating, yog li qhov kub yuav tsum tsis pub tshaj 1200 degrees. Nyob rau hauv lub xeev superheated, aluminium yog oxidized, thiab bronze alloy yog saturated nrog gases. Tsis tas li ntawd, oxide tsim thaum lub sij hawm melting ntawm no hom bronze tsis txo los ntawm kev ntxiv deoxidizers, thiab nws yog ib qho nyuaj heev kom tshem tawm nws los ntawm yaj. Cov oxide zaj duab xis muaj qhov siab melting point, uas txo qhov fluidity ntawm bronze thiab ua rau tsis lees paub. Melting yog nqa tawm heev intensive, nyob rau sab sauv txwv ntawm cua sov kub. Tsis tas li ntawd, qhov tiav lawm yuav tsum tsis txhob muab khaws cia rau hauv qhov cub. Thaum melting aluminium bronze, nws raug nquahu kom siv cov flux uas yog 50% soda tshauv thiab 50% cryolite ua txheej txheej.

Cov yaj ua tiav yog ua kom zoo ua ntej nchuav rau hauv pwm los ntawm kev qhia manganese chloride rau hauv nws, lossiszinc chloride (0.2-0.4% ntawm tag nrho pawg ntawm tus nqi). Tom qab cov txheej txheem no, cov hlau yuav tsum tau khaws cia rau tsib feeb kom txog thaum ua tiav cov roj evolution. Tom qab ntawd, qhov sib tov yog coj mus rau qhov kub thiab txias thiab nchuav rau hauv pwm.

txhawm rau tiv thaiv kev sib cais hauv cov bronze yaj nrog cov ntsiab lus siab ntawm cov hlau lead impurities (50-60%), nws raug nquahu kom ntxiv 2-2.3% npib tsib xee hauv daim ntawv tooj liab-nickel ligatures. Los yog, raws li fluxes, nws yog ib qhov tsim nyog los siv sulfate ntsev ntawm alkali hlau. Nickel, nyiaj, manganese, yog tias lawv yog ib feem ntawm bronze, yuav tsum tau nkag mus rau hauv lub yaj ua ntej txheej txheem tin ntxiv. Tsis tas li ntawd, txhawm rau txhim kho cov txiaj ntsig zoo ntawm cov hlau, nws yog qee zaum hloov kho nrog cov khoom me me raws li cov hlau refractory.