Kev lag luam metallurgical ua lub luag haujlwm tseem ceeb hauv txhua tus neeg lub neej, vim tias txhua hnub koj yuav tsum cuam tshuam nrog ntau yam khoom siv hlau. Thiab lawv yog ua los ntawm ntau yam alloys, uas tau los ntawm smelting. Hauv kev tsim cov khoom siv no, tsawg kawg yog ob lub hlau siv, thiab cov khoom siv tshwj xeeb yog siv los txhim kho cov khoom. Kab lus no yuav tshuaj xyuas ntau yam hlau-nickel alloys, lawv cov khoom thiab kev siv.

Hais txog cov khoom ntawm hlau

Ntshiab hlau yog xim nyiaj-grey thiab yog cov khoom zoo thiab tuaj yeem ua tau. Native ingots pom nyob rau hauv cov xwm muaj ib tug pronounced metallic luster thiab tseem ceeb hardness. Ntawm qhov siab thiab hluav taws xob conductivity ntawm cov khoom, nws yooj yim hloov tam sim no nrog kev pab los ntawm dawb electrons. Cov hlau muaj qhov nruab nrab refractoriness, softens ntawm qhov kub ntawm +1539 degrees Celsius thiab poob nws ferromagnetic zog. Nws yog ib qho khoom siv tshuaj lom neeg. Ntawm qhov kub thiab txias, nws yooj yim reacts, thiab thaum rhuab, cov khoom no yog txhim khu kev qha. Nyob rau hauv cov huab cua, nws yuav tsum tau them nrog ib tug oxide zaj duab xis, uas tiv thaiv lub continuation ntawm cov tshuaj tiv thaiv. Thaum raug ib puag ncig humidxeb tshwm, uas tsis tiv thaiv corrosion. Tab sis, txawm qhov no, hlau thiab nws cov alloys tau siv dav.

keeb kwm me ntsis

Invar yog ib qho alloy ntawm hlau thiab npib tsib xee, uas suav nrog 36% alloying additive. Nws tau pom thawj zaug hauv Fabkis xyoo 1896 los ntawm tus kws kho mob Charles Guillaume. Lub sijhawm no, nws tau ua haujlwm rau kev tshawb nrhiav cov hlau tsis tshua muaj rau cov qauv ntsuas ntawm qhov loj thiab ntev, uas tau ua los ntawm cov khoom kim heev platinum-iridium alloy. Ua tsaug rau qhov kev tshawb pom no, tus kws tshawb fawb tau txais Nobel nqi zog hauv Physics hauv xyoo 1920.

Lo lus "invar" hauv Latin txhais tau tias tsis hloov pauv. Qhov no txhais tau hais tias cov coefficient ntawm thermal expansion ntawm cov hlau-nickel alloy tseem nyob tas li ntawm qhov kub thiab txias ntau yam - los ntawm -80 txog 100 degrees Celsius. Cov hlau no muaj ntau lub npe: nilvar, vakodyl, nilo-alloy, radiometal. Invar yog lub cim lag luam ntawm Imphy Alloys Inc., uas yog tswv los ntawm Arcelor Mittal steel pawg.

Iron-nickel alloy

txhawm rau txhim kho cov khoom ntawm hlau, siv ntau yam khoom ntxiv, cov hlau tau txais. Cov kws tshawb fawb tau ntseeg tias nws yuav tsis yooj yim kom tau txais cov hlau-nickel alloy, coj mus rau hauv tus account lub thermodynamic zog ntawm cov hlau. Tab sis hauv kev xyaum, lawv tau khiav mus rau hauv cov teeb meem. Thaum lub sij hawm sib cuam tshuam ntawm cov hlau, thaum lub sij hawm tsim cov hlau alloy nrog npib tsib xee, raws li ib tug tshwm sim ntawm ib sab oxidation txheej txheem, hlau los ntawm lub divalent lub xeev hla mus rau lub trivalent xeev.

Vim li ntawd, cov txiaj ntsig ntawm cov alloy txo qis thiab qee yam khoom siv lub cev tsis zoo. Yuav kom daws tau qhov teeb meem no, amines thiab organic acids yog ntxiv rau cov electrolyte, uas tsim cov tebchaw uas tsis muaj solubility nrog ferric hlau. Hauv qhov no, qhov elasticity ntawm precipitate yuav zoo dua, thiab rau nws cov kev faib tawm, cov electrolytes yog tov. Qhov tshwm sim ntawm cov hlau thiab npib tsib xee yog hu ua invar.

Siv Invar alloy

Insignificant thermal expansion coefficient tso cai rau nws siv rau kev tsim khoom:

- instrument parts;

- kab xev thiab xaim rau kev ua haujlwm geodetic;

- Laser txhawb cov qauv;

- ntu ntawm saib txav, chronometer pendulums;

- dov khoom: kub dov bar thiab ntawv, txias-dov strip, seamless kav, forged tuav.

Txhawm rau kom muaj zog, txias yas deformation ntawm cov hlau-nickel alloy yog ua, thiab tom qab ntawd kev kho cua sov qis yog ua. Txhawm rau tiv thaiv corrosion ntau dua nyob rau hauv cov huab cua ib puag ncig, nws qhov chaw yog polished thiab siv cov txheej txheem tiv thaiv yog tias cov khoom tsim los siv rau hauv qhov chaw hnyav. Cov khoom tiv thaiv corrosion ntawm Invar kuj tseem yuav nce ntxiv thaum txog 12% chromium ntxiv rau nws cov muaj pes tsawg leeg, thaum nws khaws cov elasticity tas li thaum rhuab mus rau 100 degrees.

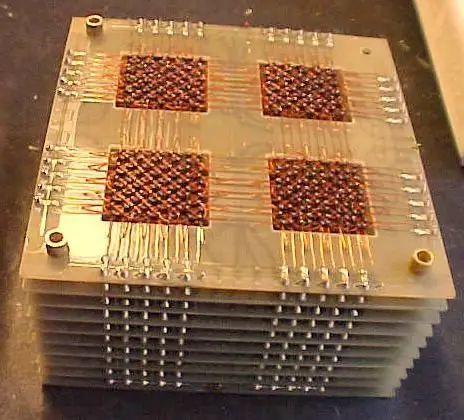

Magnetic alloys

Cov alloys no tau siv dav hauv hluav taws xob engineering. Lawv yog siv los ua cov hlau nplaum ruaj khov, transformer cores,hluav taws xob ntsuas ntsuas, electromagnets. Tib neeg tau paub ntev tias hlau yog hlau nplaum, thiab vim li ntawd, nws muaj ntau yam siv.

Ntau tom qab nws tau pom tias tib yam khoom muaj nyob hauv npib tsib xee thiab lwm yam hlau. Cov khoom tsim los ntawm cov hlau nplaum sib nqus ntawm cov hlau thiab npib tsib xee kuj muaj peev xwm tswj tau lawv tus kheej magnetic teb thaum lub sab nraud tsis muaj lawm. Ntxiv mus, qhov chaw ntawm tus kheej no rov tuaj yeem cuam tshuam lwm lub cev sib nqus.

Nickel, cob alt thiab lawv cov alloys

Cob alt thiab npib tsib xee yog cov ntsiab lus ntawm pawg hlau hlau. Tag nrho peb lub ntsiab lus muaj cov khoom zoo sib xws, tab sis kuj muaj qhov sib txawv tseem ceeb. Ob leeg hlau yog denser dua hlau thiab ntau nyuaj thiab muaj zog dua hlau. Lawv tsis tshua muaj zog hauv cov ntsiab lus tshuaj, sib txawv hauv corrosion kuj. Tsis tas li ntawd, cov hlau muaj nuj nqis rau lawv cov kev tiv thaiv ntau dua rau cov roj corrosion.

Qhov tsis zoo ntawm cob alt thiab npib tsib xee yog lawv cov tshuaj lom thiab cov nqi tseem ceeb ntawm cov hlau. Lawv pom lawv daim ntawv thov rau cov txheej txheem anticorrosive txheej ntawm cov khoom ua los ntawm carbon steels thiab hlau los ntawm electrochemical tshuaj. Thiab lawv kuj yog siv rau kev tsim khoom ntawm cov khoom thiab qhov chaw uas yuav tsum tau txhim kho lub zog thiab hardness. Qhov tshwj xeeb tseem ceeb ntawm hlau, npib tsib xee thiab cob alt alloys, uas yog hu ua koinvar, invar, supermalloy, permalloy thiab malloy, yuav tsum tau muab sau tseg. Lawv lub ntsiab kom zoo dua yog nyob rau hauv siabmagnetic zog. Cov hlau no yog siv los tsim cov hlau nplaum sib nqus rau ntau yam khoom siv hluav taws xob.

Alloy Covar

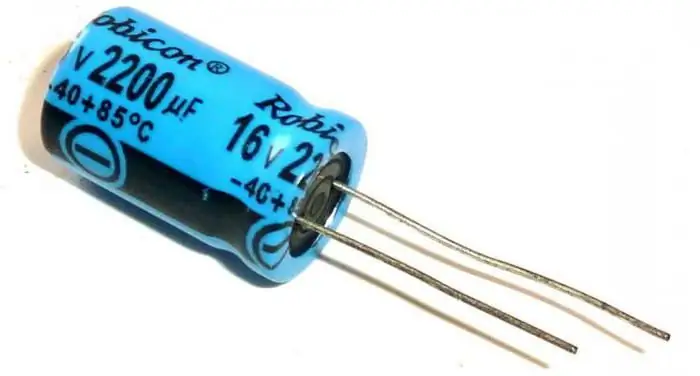

Cov khoom sib tov muaj cov hlau uas muaj cov khoom siv zoo heev. Lawv yooj yim rau txheej txheem, lawv tau yooj yim raug dov, broaching, forging thiab stamping. Thiab cov alloy ntawm cob alt, npib tsib xee thiab hlau yog lwm yam hu ua kovar. Ib qho kev xaiv zoo ua ke ntawm cov khoom siv tshuaj muab cov khoom siv nrog cov yam ntxwv zoo. Cov hlau no muaj cov thermal conductivity zoo, siab coefficient ntawm hluav taws xob resistivity, thiab linear expansion indices nyob ze rau xoom tshaj qhov kub ntau yam. Qhov tsuas yog qhov tsis zoo yog qhov tsis muaj corrosion kuj nyob rau hauv ib puag ncig ntub, yog li kev tiv thaiv txheej ntawm cov nyiaj feem ntau siv. Kovar tau dav siv hauv kev lag luam rau kev tsim khoom ntawm:

- pipes, tapes and wires;

- capacitor;

- cov khoom siv hauv ntsuas;

- nthuav dav hauv xov tooj cua hluav taws xob;

- cases hauv kev lag luam electrovacuum.

Cov hlau muaj cov cob alt kim thiab npib tsib xee, uas ua rau tus nqi ntawm cov khoom nce ntxiv, tab sis kev ua tau zoo thiab kev pab lub neej ntev npog qhov pib peev.

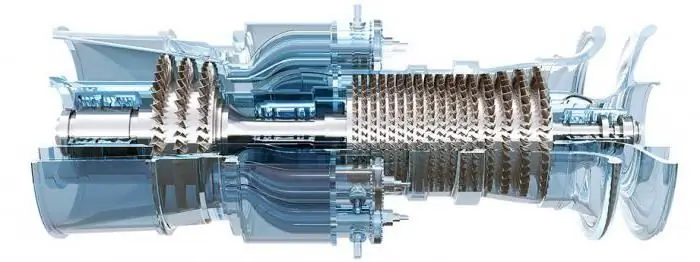

Alni alloys

Alni yog pab pawg npe rau hlau-nickel-aluminium magnetic alloys. Nrog rau kev nce hauv cov concentration ntawm txhuas thiab npib tsib xee hauv qee qhov kev txwv, qhov seem induction txo qis, thiab lub zog quab yuam nce. Feem ntau siv alloys nyob rau hauv uas aluminium los ntawm 11 mus rau18%, thiab npib tsib xee - 20-34%. Cov khoom tseem ceeb ntawm cov hlau no yog hluav taws xob conductivity, thermal conductivity thiab ductility. Tag nrho cov ntawm lawv yog cov yam ntxwv ntawm vuam zoo.

Yuav siv cov hlau nplaum hauv kev tsim cov hlau nplaum, lawv yog alloyed nrog cob alt thiab tooj liab. Hauv qhov no, cov khoom tau txais hardness thiab brittleness thiab muaj cov qauv coarse-grained. Alni alloys yog siv los ua cov khoom siv rau cov khoom siv roj turbine thiab lub dav hlau dav hlau ua haujlwm ntawm qhov kub siab tshaj 1000 degrees Celsius rau lub sijhawm ntev, ua kom cov hlau tsis muaj kev puas tsuaj.

Zoo kawg

Txhua cov hlau hnyav siv hauv kev lag luam niaj hnub no yog alloys. Piv txwv li, yuav luag tag nrho cov hlau uas tsim nyob rau hauv lub ntiaj teb no yog siv los ua hlau thiab hlau. Qhov no tuaj yeem piav qhia los ntawm qhov tseeb tias cov alloys muaj cov yam ntxwv zoo dua li cov hlau uas lawv tau txais. Nws yuav tsum raug sau tseg tias cov alloys tsim los ntawm kev lag luam muaj cov khoom zoo rau lawv: lub zog, hardness, elasticity thiab plasticity. Thiab cov hlau-nickel kuj muaj cov khoom sib nqus, uas tau txhim kho thaum lub sij hawm tsim khoom nrog kev pab los ntawm kev ntxiv alloying.