txhawm rau ntsuas qhov ua tau zoo ntawm cov khoom thiab txiav txim siab lub cev thiab cov yam ntxwv ntawm cov khoom siv, ntau cov lus qhia, GOSTs thiab lwm cov ntaub ntawv tswj hwm thiab kev tawm tswv yim yog siv. Cov txheej txheem rau kev soj ntsuam kev puas tsuaj ntawm tag nrho cov khoom lag luam lossis cov qauv ntawm tib hom khoom kuj raug pom zoo. Qhov no tsis yog ib txoj hauv kev zoo tshaj plaws, tab sis nws muaj txiaj ntsig.

txhais cov yam ntxwv

Cov yam ntxwv tseem ceeb ntawm cov khoom siv kho tshuab ntawm cov khoom muaj raws li hauv qab no.

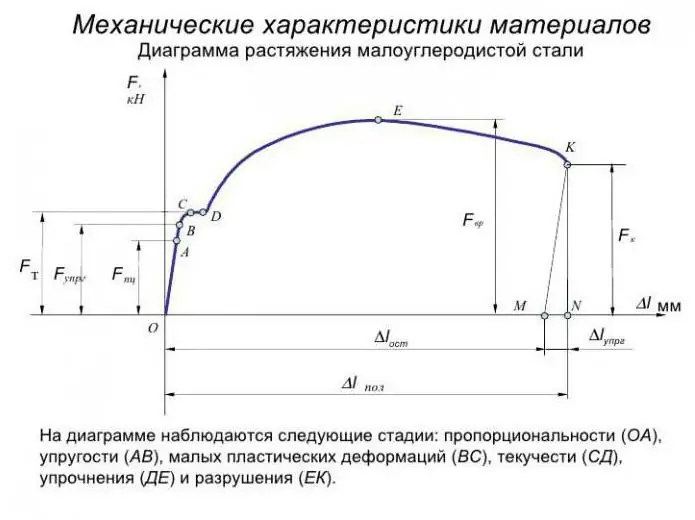

1. Tensile lub zog los yog lub zog tensile - qhov kev ntxhov siab lub zog uas tau kho ntawm qhov siab tshaj plaws ua ntej kev puas tsuaj ntawm cov qauv. Cov yam ntxwv ntawm lub zog thiab plasticity ntawm cov ntaub ntawv piav qhia txog cov khoom ntawm cov khib nyiab los tiv thaiv kev hloov pauv tsis tau ntawm cov duab thiab kev puas tsuaj nyob rau hauv kev cuam tshuam ntawm cov khoom sab nraud.

2. Lub zog ua kom muaj zog yog qhov kev ntxhov siab thaum cov kab mob seem mus txog 0.2% ntawm cov qauv ntev. Qhov no yogqhov kev ntxhov siab tsawg tshaj plaws thaum cov qauv txuas ntxiv deform yam tsis muaj kev txaus siab rau kev ntxhov siab.

3. Qhov txwv ntawm lub zog mus sij hawm ntev yog hu ua qhov kev ntxhov siab loj tshaj plaws, ntawm qhov kub thiab txias, ua rau kev puas tsuaj ntawm cov qauv rau ib lub sijhawm. Kev txiav txim siab ntawm cov yam ntxwv ntawm cov khoom siv tsom mus rau qhov kawg ntawm lub zog mus ntev - kev puas tsuaj tshwm sim ntawm 7,000 degrees Celsius hauv 100 teev.

4. Qhov kev txwv tsis pub nkag yog qhov kev ntxhov siab uas ua rau ntawm qhov ntsuas kub rau qee lub sijhawm hauv cov qauv muab elongation, nrog rau tus nqi nkag. Qhov txwv yog qhov deformation ntawm cov hlau rau 100 teev ntawm 7,000 degrees Celsius los ntawm 0.2%. Creep yog tus nqi ntawm deformation ntawm hlau nyob rau hauv tas li loading thiab kub kub rau lub sij hawm ntev. Thaum tshav kub kub tsis kam yog qhov tsis kam ntawm cov khoom tawg thiab nkag mus.

5. Lub endurance txwv yog tus nqi siab tshaj ntawm lub voj voog kev ntxhov siab thaum qaug zog tsis tshwm sim. Tus naj npawb ntawm lub voj voog thauj khoom tuaj yeem muab los yog arbitrary, nyob ntawm seb yuav ua li cas kev ntsuas cov khoom siv tau npaj. Mechanical yam ntxwv muaj xws li qaug zog thiab endurance ntawm cov khoom. Nyob rau hauv qhov kev txiav txim ntawm loads nyob rau hauv lub voj voog, kev puas tsuaj accumulates, tawg yog tsim, ua rau kev puas tsuaj. Qhov no yog qaug zog. Thiab lub zog tiv thaiv kev qaug zog yog kev ua siab ntev.

Cov khoom siv hauv engineeringkev xyaum tau muab faib ua ob pawg. Qhov thib ib yog yas, rau kev puas tsuaj uas tseem ceeb residual deformations yuav tsum tshwm sim, qhov thib ob yog brittle, collapsing ntawm me me deformations. Lawm, xws li kev faib yog heev arbitrary, vim hais tias txhua yam khoom, nyob ntawm seb cov xwm txheej tsim, muaj peev xwm coj ob qho tib si tsis yooj yim sua thiab li yas. Nws nyob ntawm qhov xwm txheej ntawm lub xeev kev ntxhov siab, qhov kub thiab txias, tus nqi lim thiab lwm yam.

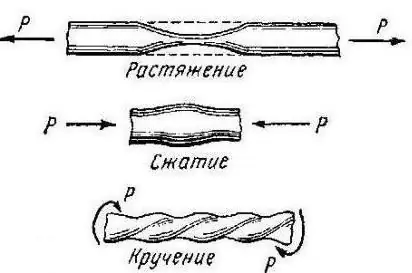

Cov yam ntxwv ntawm cov khoom siv hauv kev nro thiab compression yog eloquent rau ob leeg ductile thiab nkig. Piv txwv li, cov hlau me me yog kuaj hauv qhov nro, thaum cam khwb cia hlau yog sim hauv compression. Cam khwb cia hlau yog nkig, steel yog ductile. Cov ntaub ntawv brittle muaj zog compressive ntau dua, thaum tensile deformation yog phem dua. Yas muaj kwv yees li tib yam khoom siv ntawm cov khoom hauv compression thiab nro. Txawm li cas los xij, lawv qhov pib tseem txiav txim siab los ntawm kev ncab. Nws yog cov txheej txheem no uas tuaj yeem txiav txim siab qhov zoo ntawm cov khoom siv. Daim duab nro thiab compression muaj nyob rau hauv cov duab kos rau kab lus no.

Fragility thiab plasticity

Dab tsi yog plasticity thiab fragility? Qhov thib ib yog lub peev xwm kom tsis txhob tawg, tau txais qhov seem deformations nyob rau hauv ntau qhov ntau. Cov cuab yeej no yog txiav txim siab rau cov haujlwm tseem ceeb tshaj plaws. Khoov, kos duab, kos duab, stamping thiab ntau lwm yam kev ua haujlwm nyob ntawm tus yam ntxwv ntawm plasticity. Cov ntaub ntawv muaj xws li annealed tooj liab, tooj dag, txhuas, me me hlau, kub, thiab lwm yam. Ntau tsawg ductile bronzethiab dural. Yuav luag tag nrho cov hlau alloyed yog cov tsis muaj zog heev.

Cov yam ntxwv ntawm lub zog ntawm cov ntaub ntawv yas yog piv nrog lub zog tawm los, uas yuav tau tham hauv qab no. Cov khoom ntawm brittleness thiab plasticity yog heev cuam tshuam los ntawm kub thiab loading tus nqi. Fast nro ua rau cov khoom nkig, thaum qeeb nro ua rau nws ductile. Piv txwv li, iav yog cov khoom nkig, tab sis nws tuaj yeem tiv taus lub sijhawm ntev yog tias qhov kub thiab txias, uas yog, nws qhia tau hais tias cov khoom ntawm plasticity. Thiab cov hlau me me yog ductile, tab sis nyob rau hauv kev poob siab load nws tshwm raws li cov khoom nkig.

Variation method

Physico-mechanical yam ntxwv ntawm cov ntaub ntawv yog txiav txim los ntawm excitation ntawm longitudinal, dabtsi yog khoov, torsional thiab lwm yam, txawm ntau complex hom kev vibrations, thiab nyob ntawm seb qhov luaj li cas ntawm cov qauv, duab, hom receiver thiab exciter, txoj kev ntawm fastening thiab schemes rau thov dynamic loads. Cov khoom loj loj kuj raug kuaj los ntawm kev siv cov qauv no, yog tias cov txheej txheem ntawm daim ntawv thov nyob rau hauv cov txheej txheem ntawm kev siv lub load, excitation ntawm vibrations thiab sau npe rau lawv yog ho hloov. Tib txoj kev yog siv los txiav txim siab cov yam ntxwv ntawm cov khoom siv thaum tsim nyog los ntsuas qhov rigidity ntawm cov qauv loj. Txawm li cas los xij, txoj kev no tsis yog siv rau kev txiav txim siab hauv zos ntawm cov yam ntxwv ntawm cov khoom siv. Daim ntawv thov ntawm cov txheej txheem yog ua tau tsuas yog thaum lub geometric qhov ntev thiab ceev paub, thaum nws yog ua tau los kho cov khoom ntawm kev txhawb nqa, thiab nyob rau hauv lubkhoom - converters, tej yam kub thiab txias yuav tsum tau, thiab lwm yam.

Piv txwv li, thaum hloov pauv kev tswj hwm kub, ib lossis lwm qhov kev hloov pauv tshwm sim, cov yam ntxwv ntawm cov khoom sib txawv thaum rhuab. Yuav luag txhua lub cev nthuav dav hauv cov xwm txheej no, uas cuam tshuam rau lawv cov qauv. Txhua lub cev muaj qee yam yam ntxwv ntawm cov khoom siv uas nws tau tsim. Yog hais tias cov yam ntxwv no tsis hloov nyob rau hauv tag nrho cov lus qhia thiab nyob twj ywm tib yam, xws li lub cev hu ua isotropic. Yog hais tias lub cev thiab txhua yam yam ntxwv ntawm cov ntaub ntawv hloov - anisotropic. Cov yav tas yog ib tug yam ntxwv feature ntawm yuav luag tag nrho cov ntaub ntawv, tsuas yog mus rau ib tug sib txawv. Tab sis muaj, piv txwv li, steels, qhov twg cov anisotropy yog heev insignificant. Nws yog feem ntau pronounced nyob rau hauv tej yam ntuj tso cov ntaub ntawv xws li ntoo. Hauv kev tsim khoom, cov yam ntxwv ntawm cov khoom siv tau txiav txim siab los ntawm kev tswj xyuas zoo, qhov twg ntau yam GOSTs tau siv. Kev kwv yees ntawm heterogeneity yog tau los ntawm kev ua cov ntaub ntawv txheeb xyuas thaum cov txiaj ntsig kev xeem tau sau tseg. Cov qauv yuav tsum muaj ntau thiab txiav los ntawm ib qho kev tsim tshwj xeeb. Txoj kev tau txais cov yam ntxwv thev naus laus zis no suav hais tias yog qhov nyuaj heev.

Acoustic method

Muaj ntau txoj hauv kev acoustic rau kev txiav txim siab lub zog ntawm cov khoom siv thiab lawv cov yam ntxwv, thiab lawv txhua tus sib txawv ntawm cov tswv yim, txais tos thiab sau npe ntawm oscillations hauv sinusoidal thiab pulsed hom.acoustic txoj kev yog siv nyob rau hauv txoj kev tshawb no, piv txwv li, ntawm lub tsev cov ntaub ntawv, lawv thickness thiab nro lub xeev, thaum lub sij hawm nrhiav tsis tau. Cov yam ntxwv ntawm cov khoom siv hauv cov txheej txheem kuj tau txiav txim siab siv cov txheej txheem acoustic. Ntau ntau yam khoom siv hluav taws xob acoustic twb tau tsim thiab tsim ntau lawm, uas tso cai rau cov ntaub ntawv elastic tsis, lawv qhov kev nthuav tawm tsis pub dhau ob qho tib si hauv hom sinusoidal thiab pulsed. Ntawm lawv lub hauv paus, cov yam ntxwv ntawm cov khoom siv zog tau txiav txim siab. Yog tias siv elastic oscillations ntawm kev siv qis, txoj kev no yuav muaj kev nyab xeeb kiag li.

Qhov tsis zoo ntawm txoj kev acoustic yog qhov xav tau kev sib cuag acoustic, uas tsis yog ib txwm ua tau. Yog li ntawd, cov hauj lwm no tsis zoo heev yog tias nws yuav tsum tau ceev kom tau txais cov yam ntxwv ntawm lub zog ntawm cov ntaub ntawv. Cov txiaj ntsig tau cuam tshuam zoo heev los ntawm lub xeev ntawm qhov chaw, cov duab geometric thiab qhov ntev ntawm cov khoom nyob rau hauv kev kawm, nrog rau ib puag ncig qhov kev sim ua. Yuav kom kov yeej cov teeb meem no, ib qho teeb meem tshwj xeeb yuav tsum tau daws los ntawm txoj kev nruj me ntsis acoustic los yog, ntawm qhov tsis sib xws, ob peb ntawm lawv yuav tsum tau siv ib zaug, nws nyob ntawm qhov xwm txheej tshwj xeeb. Piv txwv li, fiberglass qiv nws tus kheej zoo rau qhov kev tshawb fawb no, vim tias qhov kev nthuav tawm nrawm ntawm elastic tsis zoo, thiab yog li ntawd qhov kawg-rau-kawg suab yog siv dav, thaum lub receiver thiab emitter nyob rau ntawm qhov chaw ntawm cov qauv.

Kev kuaj ntshav

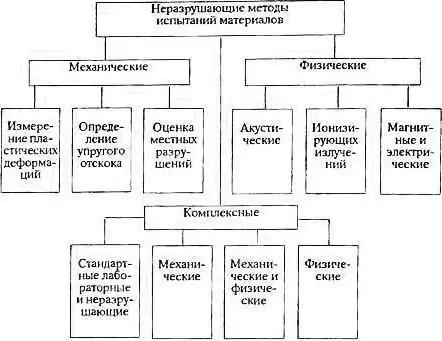

Txoj kev Defectoscopy yog siv los tswj cov khoom zoo hauv ntau qhov kev lag luam. Muaj txoj hauv kev tsis muaj kev puas tsuaj thiab kev puas tsuaj. Tsis muaj kev puas tsuaj suav nrog cov hauv qab no.

1. Magnetic flaw detection yog siv los txiav txim qhov chaw tawg thiab tsis muaj kev nkag mus. Cov cheeb tsam uas muaj xws li tsis xws luag yog cov yam ntxwv ntawm stray teb. Koj tuaj yeem ntes lawv nrog cov cuab yeej tshwj xeeb lossis tsuas yog siv cov txheej txheem sib nqus ntawm tag nrho cov nplaim. Hauv qhov chaw muaj qhov tsis xws luag, qhov chaw ntawm cov hmoov yuav hloov txawm tias siv.

2. Defectoscopy kuj tau ua nrog kev pab ntawm ultrasound. Lub nqaj taw qhia yuav raug cuam tshuam (sib cais) txawv, txawm tias muaj kev cuam tshuam tob rau hauv tus qauv.

3. Cov khoom tsis zoo hauv cov khoom tau pom zoo los ntawm txoj kev tshawb fawb hluav taws xob, raws li qhov sib txawv ntawm qhov nqus ntawm cov hluav taws xob los ntawm qhov nruab nrab ntawm qhov sib txawv. Gamma flaw detection thiab X-ray yog siv.

4. Chemical flaw detection. Yog hais tias lub nto yog etched nrog ib tug qaug zog daws ntawm nitric acid, hydrochloric acid los yog ib tug sib tov ntawm lawv (aqua regia), ces nyob rau hauv cov chaw uas muaj tsis xws luag, ib tug network tshwm nyob rau hauv daim ntawv ntawm cov kab txaij dub. Koj tuaj yeem siv txoj hauv kev uas cov ntawv luam tawm sulfur raug tshem tawm. Nyob rau hauv qhov chaw uas cov khoom yog inhomogeneous, sulfur yuav tsum hloov xim.

Txoj Kev Ua Phem

Txoj kev ua kom puas ntsoog tau ib nrab tshem tawm ntawm no. Cov qauv raug kuaj rau kev khoov, compression, nro, uas yog, siv txoj kev puas tsuaj zoo li qub. Yog cov khoomraug kuaj nrog sib txawv cyclic loads ntawm kev cuam tshuam dabtsi yog khoov - dynamic zog yog txiav txim. Macroscopic txoj kev kos duab dav dav ntawm cov qauv ntawm cov khoom siv thiab hauv cov ntim loj. Rau kev kawm zoo li no, cov qauv tshwj xeeb polished yog xav tau, uas yuav raug etching. Yog li, nws muaj peev xwm txheeb xyuas cov duab thiab kev npaj ntawm cov nplej, piv txwv li, hauv cov hlau, muaj cov muaju nrog deformation, fibers, plhaub, npuas, tawg thiab lwm yam inhomogeneities ntawm cov alloy.

Cov txheej txheem Microscopic kawm txog microstructure thiab qhia qhov tsis xws luag. Cov qauv yog ua ntej hauv av, polished thiab ces etched nyob rau hauv tib txoj kev. Kev sim ntxiv no suav nrog kev siv hluav taws xob thiab kho qhov muag tsom iav thiab X-ray diffraction tsom xam. Lub hauv paus ntawm txoj kev no yog kev cuam tshuam ntawm rays uas tawg los ntawm cov atoms ntawm ib yam khoom. Cov yam ntxwv ntawm cov khoom yog tswj los ntawm kev tshuaj xyuas X-ray diffraction qauv. Cov yam ntxwv ntawm cov khoom siv txiav txim siab lawv lub zog, uas yog qhov tseem ceeb tshaj plaws rau kev tsim cov qauv tsim kom ntseeg tau thiab muaj kev nyab xeeb hauv kev ua haujlwm. Yog li ntawd, cov khoom raug sim ua tib zoo thiab los ntawm ntau txoj kev nyob rau hauv txhua yam kev mob uas nws muaj peev xwm txais tau yam tsis tau poob ib theem siab ntawm txhua yam yam ntxwv.

Control method

Rau qhov kev sim tsis muaj kev puas tsuaj ntawm cov yam ntxwv ntawm cov ntaub ntawv, kev xaiv txoj kev zoo yog qhov tseem ceeb heev. Qhov tseeb tshaj plaws thiab nthuav hauv qhov no yog cov txheej txheem ntawm kev kuaj pom qhov tsis zoo - kev tswj tsis raug. Ntawm no nws yog ib qho tsim nyog yuav tsum paub thiab nkag siab qhov sib txawv ntawm cov txheej txheem rau kev siv cov kev kuaj pom qhov tsis zoo thiab cov txheej txheem rau kev txiav txim siab lub cev.mechanical yam ntxwv, txij li thaum lawv yog qhov sib txawv ntawm ib leeg. Yog tias tom kawg yog raws li kev tswj hwm ntawm lub cev tsis zoo thiab lawv qhov kev sib raug zoo tom qab nrog cov yam ntxwv ntawm cov khoom siv, tom qab ntawd kev kuaj pom qhov tsis zoo yog raws li kev hloov pauv ntawm hluav taws xob ncaj qha uas tau cuam tshuam los ntawm qhov tsis xws luag lossis dhau los ntawm ib puag ncig tswj.

Qhov zoo tshaj plaws, tau kawg, yog kev tswj xyuas nyuaj. Qhov nyuaj yog nyob rau hauv kev txiav txim siab ntawm lub cev tsis zoo, uas tuaj yeem siv los txheeb xyuas lub zog thiab lwm yam ntawm lub cev thiab cov yam ntxwv ntawm cov qauv. Thiab tseem, tib lub sij hawm, ib qho kev pom zoo ntawm txoj kev los tswj cov txheej txheem tsis xws luag yog tsim thiab tom qab ntawd siv. Thiab, thaum kawg, ib qho kev ntsuam xyuas ntawm cov khoom siv no tshwm sim: nws qhov kev ua tau zoo yog txiav txim siab los ntawm tag nrho cov kev ntsuas uas tau pab txiav txim siab tsis muaj kev puas tsuaj.

Mechanical test

Cov khoom siv cuab yeej cuab tam ntawm cov khoom raug sim thiab ntsuas nrog kev pab ntawm cov kev xeem no. Hom kev tswj no tau tshwm sim ntev dhau los, tab sis tseem tsis tau poob nws qhov tseeb. Txawm tias cov khoom siv high-tech niaj hnub no feem ntau raug thuam los ntawm cov neeg siv khoom. Thiab qhov no qhia tias cov kev xeem yuav tsum tau ua kom zoo dua qub. Raws li twb tau hais lawm, kev ntsuam xyuas tshuab tuaj yeem muab faib ua ob hom: static thiab dynamic. Cov qub xyuas cov khoom lossis cov qauv rau torsion, nro, compression, dabtsi yog khoov, thiab tom kawg rau hardness thiab cuam tshuam lub zog. Cov cuab yeej siv niaj hnub no pab ua cov txheej txheem tsis yooj yim heev nrog kev ua haujlwm siab thiab txheeb xyuas txhua yam teeb meem kev ua haujlwm. Cov khoom ntawm cov khoom no.

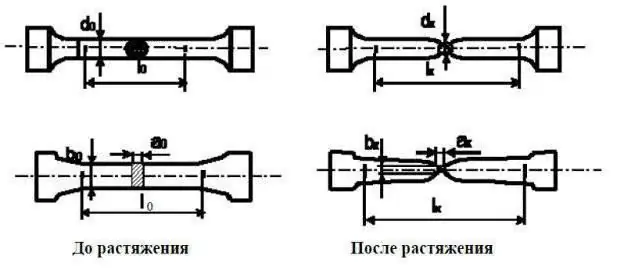

Kev ntsuas kev nruj tuaj yeem qhia qhov tsis kam ntawm cov khoom siv rau cov teebmeem ntawm kev siv tas li lossis nce tensile stress. Cov txheej txheem yog qub, sim thiab nkag siab, siv tau ntev heev thiab tseem siv dav. Cov qauv yog ncab raws qhov ntev axis los ntawm kev sib txuas hauv lub tshuab kuaj. Lub tensile tus nqi ntawm cov qauv yog tas li, lub load yog ntsuas los ntawm ib tug tshwj xeeb sensor. Nyob rau tib lub sij hawm, lub elongation yog saib xyuas, raws li zoo raws li nws ua raws li cov ntaub ntawv load. Cov txiaj ntsig ntawm cov kev sim no yog qhov tseem ceeb heev yog tias yuav tsum tau tsim cov qauv tshiab, txij li tsis muaj leej twg paub tias lawv yuav coj li cas hauv kev thauj khoom. Tsuas yog kev txheeb xyuas ntawm tag nrho cov kev txwv ntawm elasticity ntawm cov khoom tuaj yeem qhia. Kev ntxhov siab siab tshaj plaws - lub zog tawm los ua rau lub ntsiab lus ntawm qhov siab tshaj plaws uas cov khoom muab tuaj yeem tiv taus. Qhov no yuav pab xam cov npoo ntawm kev nyab xeeb.

Hardness test

Qhov tawv ntawm cov khoom yog xam los ntawm cov qauv ntawm elasticity. Kev sib xyaw ua ke ntawm fluidity thiab hardness pab txiav txim siab elasticity ntawm cov khoom. Yog tias cov txheej txheem thev naus laus zis muaj cov haujlwm xws li broaching, dov, nias, ces nws tsuas yog tsim nyog kom paub qhov loj ntawm cov yas deformation. Nrog cov yas siab, cov khoom siv yuav tuaj yeem nqa txhua yam hauv qab qhov tsim nyog. Kev ntsuam xyuas compression kuj tseem tuaj yeem ua ib txoj hauv kev los txiav txim siab qhov npoo ntawm kev nyab xeeb. Tshwj xeeb tshaj yog tias cov khoom tawg yooj yim.

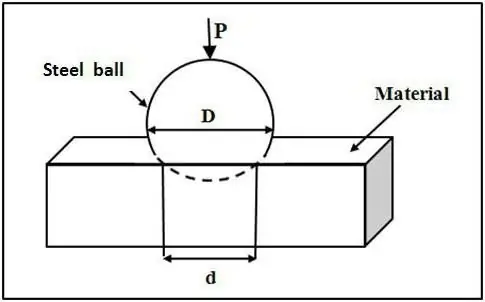

Hardness yog sim sivIdentator, uas yog ua los ntawm cov ntaub ntawv nyuaj heev. Feem ntau, qhov kev sim no yog ua raws li txoj kev Brinell (ib lub pob yog nias rau hauv), Vickers (lub pyramid-shaped identer) lossis Rockwell (ib lub khob siv). Ib qho kev txheeb xyuas raug nias rau hauv qhov chaw ntawm cov khoom siv nrog ib qho kev quab yuam rau ib lub sij hawm ntawm lub sij hawm, thiab tom qab ntawd cov imprint seem ntawm cov qauv yog kawm. Muaj lwm qhov kev sim siv dav dav: rau kev cuam tshuam lub zog, piv txwv li, thaum qhov kev tiv thaiv ntawm cov khoom raug soj ntsuam thaum lub sijhawm ntawm kev thov ntawm kev thauj khoom.